GALVANIZED WIRE

Hot-dip galvanization of metal wires is the most effective and appropriate process to protect steel from corrosion. The galvanized mild steel wires, as well as hard or patented high carbon steel wires for general technical uses, have been studied and developed to respond specifically to the individual needs and to meet all requirements needed by subsequent processing on automatic machines.

GALVANIZED WIRE

Hot-dip galvanization of metal wires is the most effective and appropriate process to protect steel from corrosion. The galvanized mild steel wires, as well as hard or patented high carbon steel wires for general technical uses, have been studied and developed to respond specifically to the individual needs and to meet all requirements needed by subsequent processing on automatic machines.

USES

- Wire for rockfall protection systems, mesh and gabions

- Wire for electrowelded mesh and fences

- Wire for fencing

- Wire for cable armouring

- Wire for ropes

- Wire for springs

- Wire for lightning protection

- Wire for bucket handles and paint rollers

- Wire for bent metal elements for the automotive industry

- Wire for bailing of cellulose

- Chain link fences for sport centers

TECHNICAL DATA

STEEL – UNI EN 16120-2

from C4D to C86D

DIAMETERS

from 0,80 to 16,00 mm

TENSILE STRENGTH

from 380 a 2.000 N/mm2

COATING – UNI EN 10244-2 T1

zinc 99,995% – class A/B/C/D

Upon specific request, it is possible to find an agreement on packaging, diameter, coating mass and tensile strength.

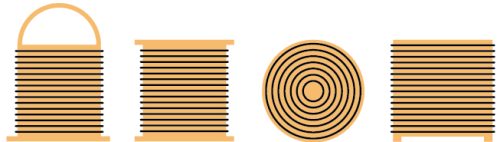

PACKAGING

| Ø diameters (mm) | weight (kg) |

| 2,00-12,00 | 1000-2000 |

| Ø diameters (mm) | weight (kg) |

| 0,80-7,00 | 25-100 |

| 8,00-10,00 | 40-50 |

| Ø diameters (mm) | weight (kg) |

| 0,80-1,60 | 200-250 |

| 1,70-12,00 | 650-2400 |

| Ø diameters (mm) | weight (kg) |

| 5,50-16,00 | 2000-2400 |

REDRAWN GALVANIZED WIRE

Intended for special uses where high surface quality, constant tensile strength and a solid coating are required. For example, bent articles from wire, such as bucket handles, coat hangers, jar closures. The product has reached a high level of reliability, which ensures minor interruptions and therefore less production losses, reduction of waste and time.