The carefully selected raw materials, such as homogeneous steel and pure electrolytic zinc, the advanced and reliable technological processes and the scrupulous continuous quality controls ensure the production of an output with uniform mechanical and chemical-physical characteristics that respond to the latest international standards and customer requests.

In October 1992, the entire quality management system of ‘Mazzoleni’ obtained the certification of compliance with the UNI EN ISO 9001 standard. The production system certified by the Italian Institute for Quality Assurance guarantees constant results and full compliance of the products.

The company defines as the main principles of its quality policy:

– customer orientation: the company focuses on satisfying the customer´s needs, keeping into account and acting with respect of the regulations and legal norms;

– process approach: it identifies the different activities within the organization, plans and monitors them in order to reach the planned goals and results, the responsibilities and the allocated resources.

– leadership: it guarantees the allocation of all the necessary resources. It ensures that the planned goals are compliant with the context and the strategic guidelines. The efficiency of the Quality Management System is examined annually with the aim of a continuous improvement;

– risk and opportunity assessment: the organization plans its processes with a risk-based thinking (RBT) approach in order to act in the most suitable way and to assess all the risks associated to the processes and to exploit all the possible opportunities;

– staff involvement: aware of the fact that the involvement of the staff and the proactive participation of all employees is of primary importance, it promotes the development of professional skills with adequate training;

– improvement: is the goal of the Quality Management System. The organization makes the investments necessary to achieve the goals and reports them in the so called “annual quality improvement plan”.

Mazzoleni Trafilerie Bergamasche S.p.A. produces steel wires from completely recyclable natural elements.

In fact, steel can be fully recycled as many times, without compromising its original properties.

To certify its commitment, the company strongly invested in digitalization, reorganization of the production site and R&D in order to reduce the impact of the main raw materials used in the production process.

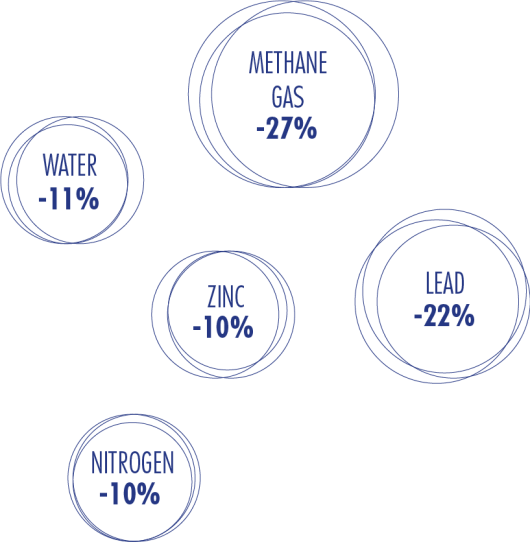

This massive intervention in 2018 has allowed the company to decrease the consumption of water by 11%, methane gas by 27%, lead by 22%, nitrogen by 10% and zinc by 10%.

Moreover, in 2010 a photovoltaic system has been installed which supplies about 18% of the energy needs of the entire production site.

“Mazzoleni” has always been involved in the supply of black annealed wire for the recycling industry of the main sectors: paper, plastic and municipal waste, which allows the company to play a key role in the circular economy.

Furthermore, “Mazzoleni” is committed in the reuse, for example, of the heptahydrate iron sulphate which is mainly used in agriculture. This chemical element allows to correct the pH of the soil, to reduce the alkalinity of saline soils, to promote the photosynthesis and to prevent the iron chlorosis.

SPECIFIC CONSUMPTION

FROM 2018 TO PRESENT